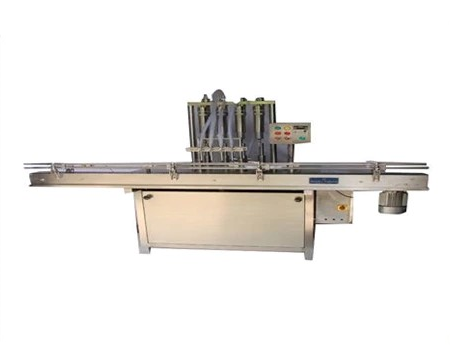

Volumetric Filling Machine Manufacturer

Our Automatic Volumetric Liquid Filling Machine is developed for High-performance, Power-efficiency, and precision-driven systems that support continuous automatic operations in the packaging industry. We have constructed our automatic machine to deliver consistent results in continuous and speedy packaging productions. Our machine is equipped with a volumetric piston-based system or gravity-filling mechanism for providing constant liquid volumes into bottles or containers.

Our machine can handle both free-flowing and semi-viscous liquids such as edible oil, syrups, dairy products, juices, shampoo, and chemicals while maintaining a hygienic environment with easy cleaning and maintaining features. In this modern era, more than 58% of both mid-scale packers to large-scale packaging industries rely on automatic liquid filling machines for consistent results over a long period of time.