- Home

- About Us

- Product Range

- Liquid pouch filling machine

- Powder Filling Machine

- Powder pouch filling machine

- Conveyors

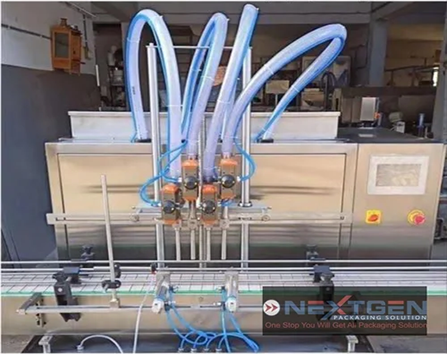

Prominent & Leading Retailer from Ahmedabad, we offer pneumatic liquid filling machine, pneumatic viscous oil filling machine, semi automatic liquid filling machine and oil filling machines. Semi automatic filling machines are suitable for filling almost any liquid, from free flowing fragrances to drinks, through to viscous syrups and adhesives and even liquids containing particles such as food products. Nextgen Packaging Machinery manufacturers a wide range of liquid filling machine , our range of liquid filling start with semi automatic liquid filling to fully automatic liquid filling machines . On this page , we will share more details about semi automatic liquid filling machines. also known as volumetric semi automatic liquid filling or syringe based semi automatic liquid filling machines.

For precise liquid dispensing into containers in small to medium scale production environments, a semi automatic liquid filling machine is a practical and affordable option. These devices, which provide accurate filling by mechanisms like pistons, peristaltic pumps, or gravity systems, are frequently employed in the food and beverage, cosmetics, pharmaceutical, and chemical sectors. They are flexible for different container sizes and liquid viscosities, but they need an operator to start each fill cycle. Businesses looking to increase filling accuracy and speed without the greater expenditure of fully automated systems will find them perfect due to their small size, simplicity of use, and dependable performance.

A semi automatic filling machine for all kinds of bottles is a flexible and effective way to deal with a variety of liquid, paste, or semi-viscous items from a variety of industries, including chemicals, food and beverage, cosmetics, and pharmaceuticals. Glass, plastic, and metal containers are among the various bottle shapes and sizes that it can fit while maintaining precise and reliable fills thanks to its adjustable nozzles, volume control, and anti-drip features. Small to medium-sized production lines benefit greatly from this kind of machine since it combines automated elements with manual control (often via a foot pedal or timer) to boost output, cut waste, and uphold hygienic requirements.